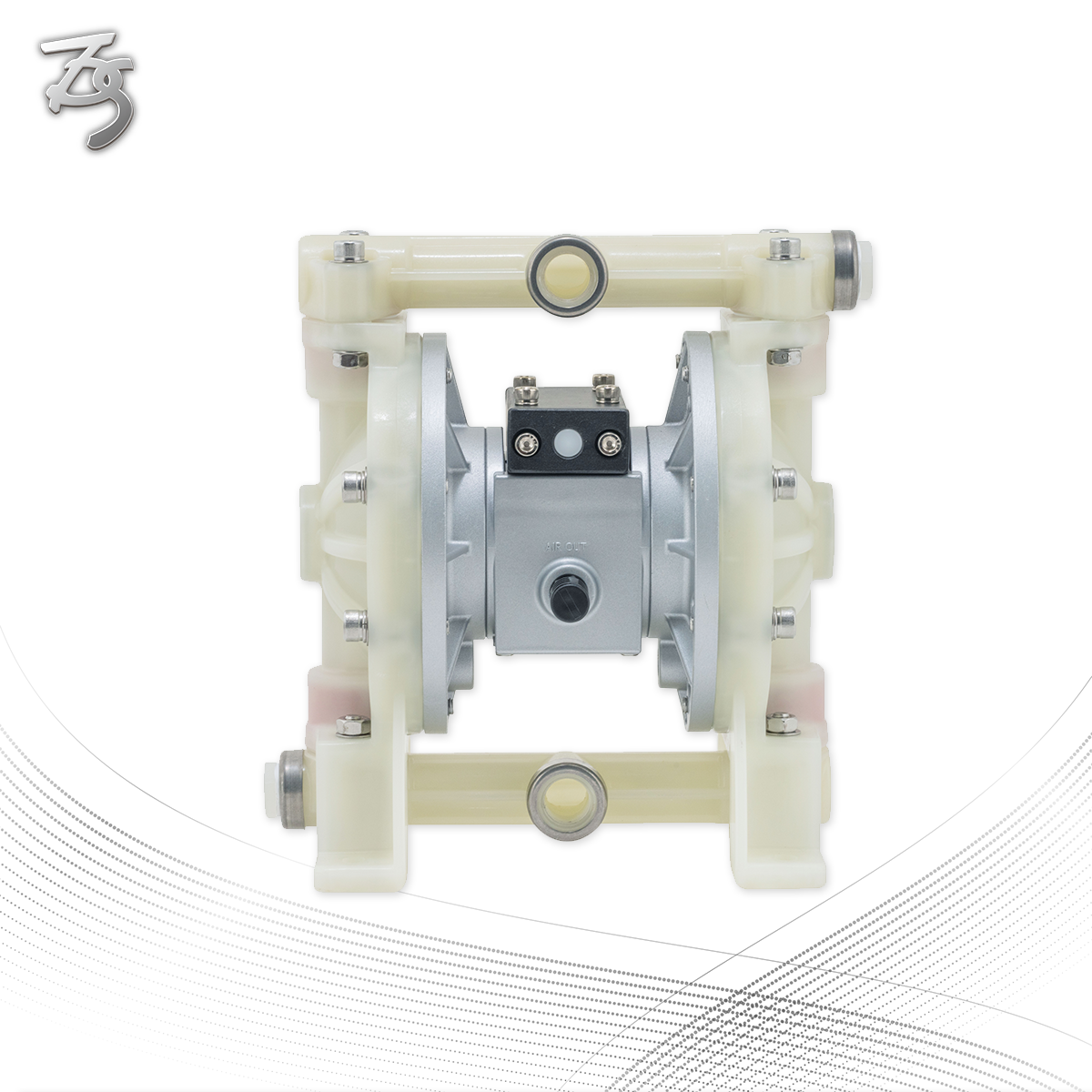

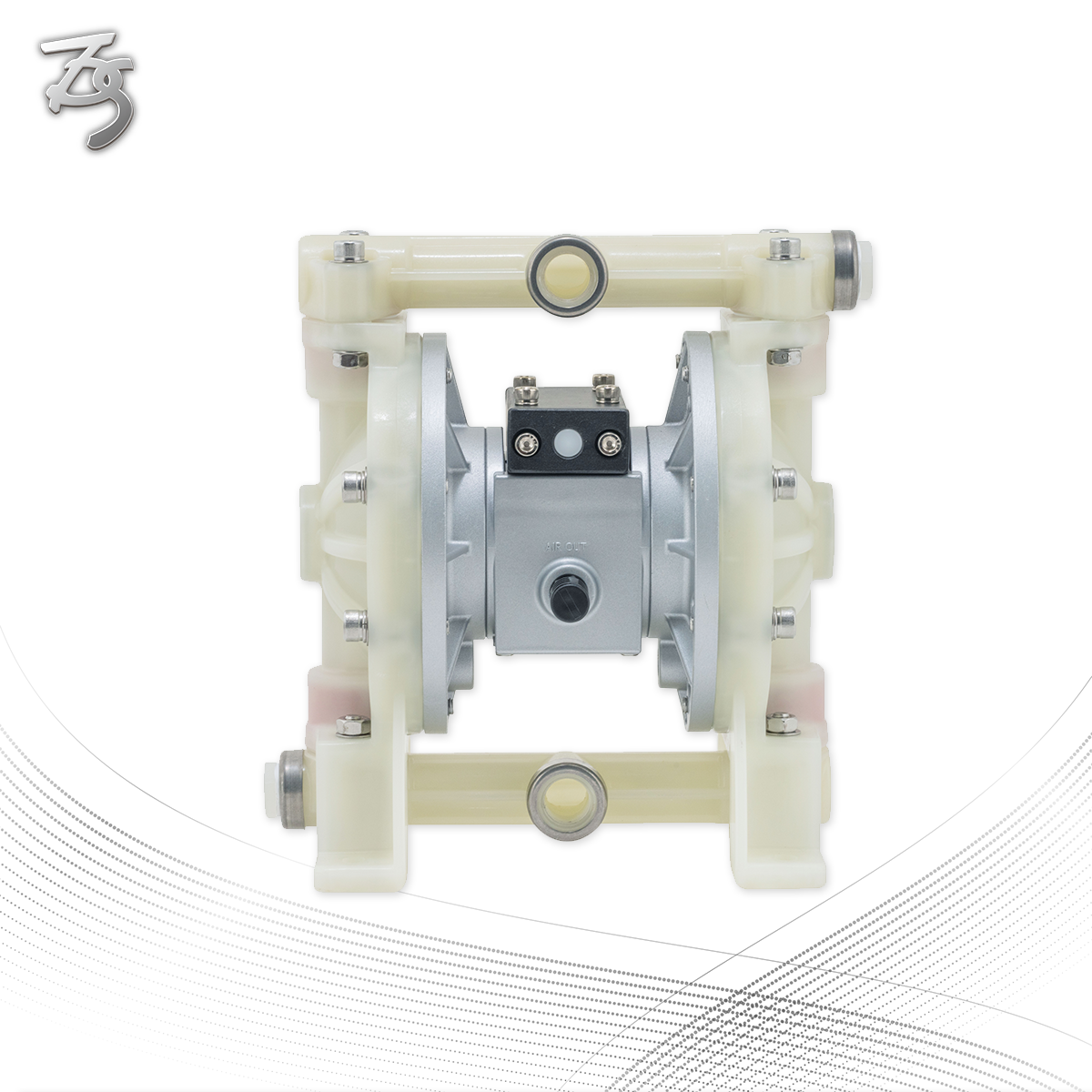

Embark on a journey of convenience and efficiency with our double diaphragm pump. Designed with dual diaphragms, it boasts enhanced pumping capabilities and unwavering reliability, setting a new standard in fluid transfer technology. The pump's compact size, along with its user-friendly features, renders it suitable for a wide array of applications, ensuring ease of use and adaptability.

Our pump is built to endure, with a durable construction and corrosion-resistant materials that guarantee long-lasting performance, even in the most challenging of environments. No matter the demands of your application, our double diaphragm pump is up to the task.

If you're looking to enhance your fluid transfer operations, our double diaphragm pump is the answer. Contact us right now for more product details!

- Wetted Body Material: Polypropylene + Glass Fiber

- Center Air Chamber Material: Aluminum Alloy

- Diaphragm material: Teflon (TFM), Santoprene (STP)

- It is suitable for the transportation of most acid & alkali liquids, but not suitable for nitric acid, aqua regia, benzene solvents, and gasoline...

- Diaphragm Specification

Material:

TFM (T) - Temperature Range: -30°C to +130°C

Stantoprene® (O) - Temperature Range: 0°C to +80°C

➤Specification

- Liquid inlet & outlet: 1/2" PT(BSP)

- Air inlet: 1/4" PT(BSP)

- Air outlet: 1/4" PT(BSP)

- Min Air Inlet Pressure: 0.8 Bar (kgf/cm²) or 11.6 psi

- Max Air Inlet Pressure: 7.0 Bar (kgf/cm²) or 101.5 psi

- Best Air Inlet Pressure Range: 1.5 to 3.5 Bar (kgf/cm²) or 21.75 psi to 50.76 psi

- Discharge Volume Per Cycle:140 ml/cycle

- Max Solids Handling: Up to 2 mm in diameter

- Max Air Consumption:530Liter/Per Min.;18.72 Scfm/Per Min

- Max Wet Suction Lift: 6.7 m

- Packing Dimensions: 29Lx20Wx30H(cm), 0.62Cuft

- Net Weight: 4 KG

- Max flow rate: 12.16 Gallon/Per Min. ; 46 Liter/Per Min.

- Liquids Serviceability: Suitable for most acidic and alkaline liquids, excluding strong acidic and alkaline liquids such as nitric acid, aqua regia, organic solvents, and petrol.

➤Product Advantage

Air Driven Double Diaphragm Pump possesses unique advantages that set it apart from other pumps, including high versatility, safety, and portability.

Across a spectrum of industries including electronics, petrochemicals, environmental protection, and food, the pneumatic diaphragm pump has established itself as a preeminent choice due to its versatile applications.

Here are the distinct advantages of the pneumatic double diaphragm pump:

- [Explosion-proof] - The pneumatic-driven design generates no electric sparks, making it safe to use in flammable and explosive environments.

- [Acid and Alkali Resistance, Solvent Resistance] - The diaphragm design isolates the transported fluid from the driving pneumatic chamber, allowing it to handle dangerous liquid solvents containing strong acids, strong alkalis, corrosive, and volatile substances without posing harm to the environment or users.

- [High Safety] - Operating at pressures ranging from 1 to 8.3 Bar, the pneumatic-driven circulation principle allows for extended dry-running periods without concerns of overheating. Additionally, in case of pipeline blockage and resulting load, the pump stops due to pneumatic balance, preventing the risk of continuous pressure buildup, pipeline rupture, or liquid leakage.

- [Capability to Transport Fluids with Particles] - Thanks to its diaphragm siphon design, the pneumatic double diaphragm pump is highly suitable for transporting fluid containing particles. As long as the particle size remains within the allowable limits of various pump specifications, it ensures smooth fluid transportation without the risk of blockages.

- [Low Shear Force]- The diaphragm siphon design offers the characteristic of low shear force during transportation, ensuring the integrity of fluid particles and preventing their destruction during conveyance. It is particularly suitable for transporting "shear-sensitive substances," such as jam, tapioca pearls, condiments, shampoo, wine, coconut, and more.

- [Capability to Transport Viscous Fluids]- With pneumatic-driven and siphon principles, there is no need to consider motor torque or the issue of viscous fluid dry-running. The pneumatic diaphragm pump can effectively handle fluids with viscosity, such as resin, slurry, paint, and coatings.

- [Compact Size, Lightweight, and Portability]- Powered by compressed air, the pneumatic diaphragm pump operates simply by connecting to an air supply line, eliminating the need for heavy motor systems. This grants significant advantages and convenience in terms of size, weight, mobility, and operation.

The pneumatic diaphragm pump adopts our latest self-developed patented air valve design, allowing it to operate with a minimum air pressure of only 1.0Bar. It possesses numerous advantages, including high efficiency, extended lifespan, and low maintenance costs. Moreover, its inherent design principles eliminate the need for complex control systems, making it highly versatile and applicable across various industries, such as automation, wastewater treatment, mining, shipbuilding, electroplating, chemical, electronics, construction, petrochemical, food, pharmaceuticals, and more. It's safe to say that the pneumatic diaphragm pump is one of the most widely used pumps in the world! Should you have any inquiries or requirements, please feel free to contact us. Thank you!

- Easy to move and install.

- Low maintenance cost.

- Can run dry for extended periods without damage.

- Ensures 100% no-stall work efficiency.

- Comes with a one-year warranty period, with a maximum of three years warranty for the diaphragm.

- Suitable for conveying corrosive and abrasive substances.

- Capable of handling high viscosity fluids.

- Does not affect the integrity of the conveyed material.

- Safe to use in flammable and explosive environments.

- Pipe blockage does not lead to excessive load, overheating, or explosions.

- Provides high accuracy in its operation.

➤Product Certifications

We are professional manufacturer of air-operated double diaphragm pump in Taiwan. Dedicated to product research and development, we now have CE, ATEX, and ISO9001 quality certifications. We take high-quality, swift service, innovative technology, honesty, and trustworthiness as our guiding principles.